From an idea to a finished special coin

The many stages of a special coin, from initial design right up to the much sought-after collector’s item in proof or brilliant uncirculated quality.

Coin design

Before a special coin can be minted, its design must be finalised. Within the specified subject parameters, coin designers produce an image that needs to be effective even at a very small scale.

1. Design

Every coin starts with an initial design. Using hand-drawn and digital sketches, models are produced in modelling clay and plaster. The aim is to end up with a digital model.

2. Oversized plastic model

As soon as the digital design is complete, it is cut into a plastic model at seven times the actual size. This

allows all the design’s details and relief structures to be precisely examined and adjusted where necessary.

Making the positive and negative dies

Once the design has been approved, it is cut into a positive die. This positive die is then used to produce all the other dies for making the coins.

3. Producing the positive die

To transfer all the design’s details to the unhardened steel, the coin image is reduced to the actual size of the coin and cut into an unhardened steel cylinder to produce a positive die. This process takes between 12 and 18 hours.

4. Producing the negative (minting) die

The positive die is subsequently used to create the actual negative minting dies, which are then annealed at around 800°C. This step is repeated twice. After another pressing process, the external shape of the die is rounded off in line with the requirements of the minting machines. Finally, the dies are hardened at a temperature of up to 1,100°C. This gives the dies the necessary hardness to allow the coins to be minted to a high level of precision. After hardening, a laser is used to make the relief surface matt in different grey tones. This lends greater depth and liveliness to the coins. For a larger aesthetic contrast, the surfaces adjoining the relief are polished to a high shine.

5. Vacuum-coating of the minting die

Physical vapour deposition is used to apply a thin but hard layer of chromium to the printing dies. This coating protects the die’s surface and improves its hardness and durability. Once coated, a pair of minting dies can be used to mint up to a million circulating coins, or between 600 and 800 special coins.

Minting

The actual minting of the coins is the key stage in the production process. The ingredients in this recipe are: minting presses, minting dies, blanks and lots of know-how.

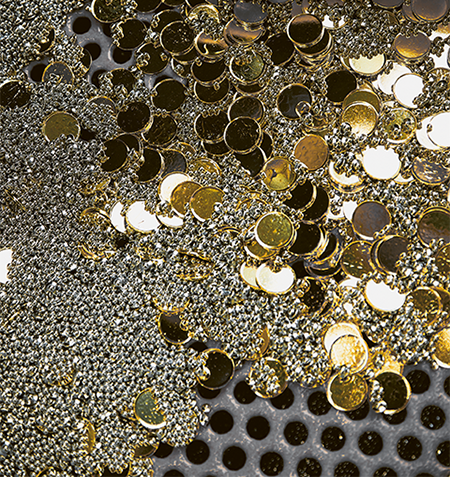

6. Making the blanks and preparing them for minting

The blanks are sourced externally and are subject to strict quality controls (material, weight, diameter, thickness and conductivity). Blanks for minting coins in standard coinage or brilliant uncirculated quality are pressed without further preparation, just like circulating coins, whereas blanks intended for proof quality undergo a preparatory process. This involves annealing, pickling, polishing, washing and stain-free drying. The aim is to achieve an optimal surface quality.

7. Preparing the press and minting the coins

The special coins are minted either in a reduced run, for coins in brilliant uncirculated quality, or individually with double striking, for coins in proof quality.

8. Inspection and packaging

Once minted, all the coins undergo rigorous inspection. Coins in proof quality are placed in transparent capsules that both present and protect them. Brilliant uncirculated coins are sealed in blister packs or put together in collector’s coin sets.